- NL-Renkum HuijsWatanuki 20151203 TuinHuisje09 Eerste laag van dak gelegd

Gallery: Germany Berlin Bohlmans Ruh 2007. DRK/German Red Cross Training: Setting up of ERU Emergency Hospital

Gallery

Sterilization of medical supplies by Steam. 3rd Edition

Sterilization of medical supplies by Steam

Sterilization of medical supplies by Steam

3rd Edition 2010. Publisher: MHP-Verlag, Germany

ISBN 978-38-8681-102-1

In a hospital or clinic it is necessary that all equipment and materials used for treating patients are absolutely safe for use: the chance for spreading of diseases should be kept as small as possible. Cleaning, decontamination and sterilization are important methods in this battle against this ever present threat. Especially since the fatal disease AIDS became so powerful and spread world wide, the demand for proper procedures for infection control gained momentum enormously. Diseases such as Hepatitis B, known to be transmitted through contaminated surgical instruments, stimulated the need for stricter guidelines for disinfection and sterilization.

This book focuses on the most common and most safe method used for sterilization in the Central Sterile Service Departments in healthcare institutions: sterilization by pressurised high temperature steam.

A first major step to improvement of sterile supply is the training of all personnel involved (technicians, staff and users). Moreover, in the recently published European standards on sterilization, education is required of everybody involved in sterilization, whether it concerns the manufacturer of the sterilizing equipment or the technician maintaining or using it. This series of books provides a foundation needed to fulfil this requirement. Originally intended to educate technical service personnel in remote health institutions, it has grown into a textbook that can be used by anyone interested in sterilization.

The World Federation for Hospital Sterilization Sciences (WFHSS) is pleased to recommend the book to all their members and all others involved in sterilization practices.

Ordering

You can order this book at MHP Verlag here

Foreword by the author

Good old days in Ghana: 1985. The HES team at the Mary Theresa Hospital in Dodi Papase where we just did install a major electrical supply network.

It already has been almost 28 years since I left for Ghana, West Africa, as a technician, where I would stay for 7 years. I was responsible for the setting-up of a maintenance service for the hospitals within the healthcare system of the Catholic Church. Initially the work was focussing mainly on the actual repairs and maintenance of equipment in all its variety. In the later years the tasks moved to more organisational work and most of all training. I found out that for most equipment a wide range of training and study material was available. However for sterilization the information I could find was limited to often very brief instructions for use of equipment without further background information. After finishing the contract in Ghana I was asked to start preparing training material for hospital technicians. I thus choose sterilization as one of the first subjects to cover. It was in the early nineties, the time that in the Netherlands the world of sterilization was very much in motion. The Netherlands was in the forefront of the developments in this domain. The Guidelines on Sterilisation and Sterility were just formulated and became the basis for the first European Standards for sterilisation. The trade quickly professionalized.

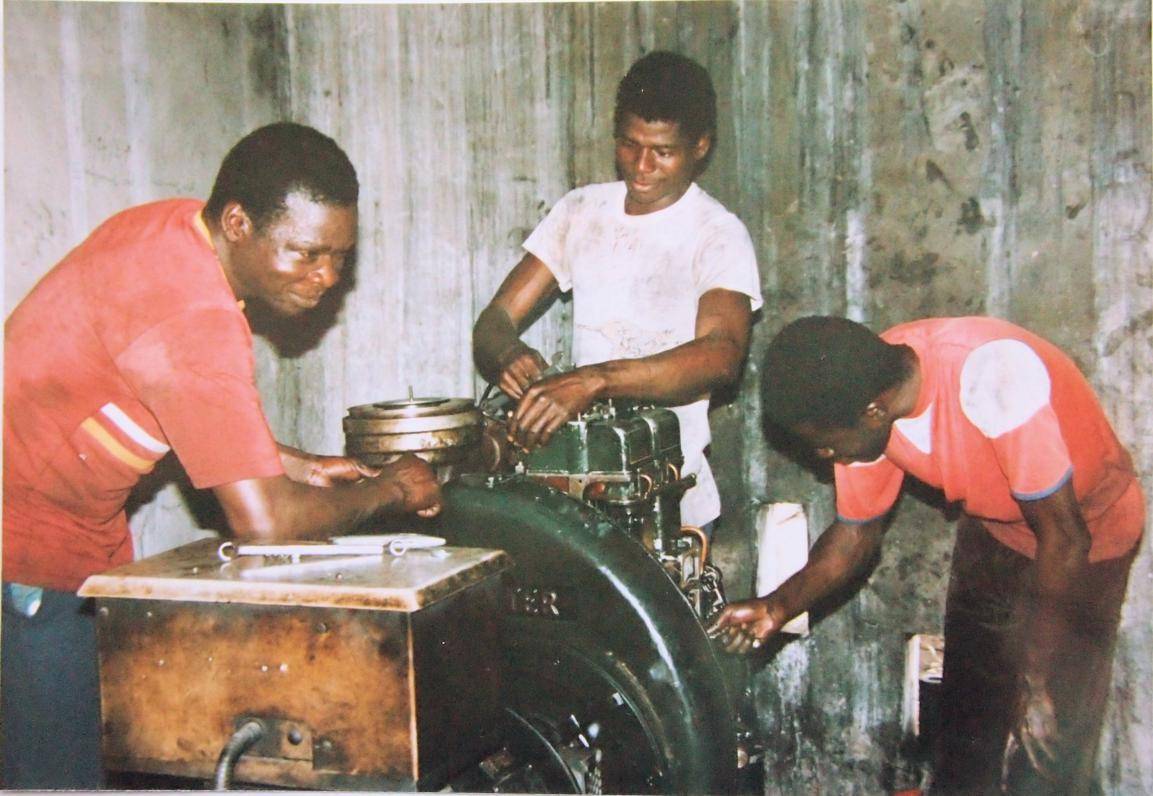

Servicing a good old HA3 Lister power plant at Duayaw Nkwanta Hospital, Ghana. 1986. With HES technicians: Sylvester Akparibo, Emmanuel Atubisah and?

I came to realize that I severely underestimated my efforts of writing a book on the topic! In order to be better prepared I attended a training with Mr. Machiel Jan Bot of Medithema, who introduced me with great enthusiasm into the world of micro-organisms, infection prevention and sterilization. For gathering information I got in touch with many sterilization-related companies and among others the RIVM: the Institute for Public Health and the Environment of the Netherlands. At that time the late Mr. Jack van Asten was pushing a scientific approach to sterile supply in hospitals throughout The Netherlands and through his department was enforcing improved quality control and validation of sterilization processes. From the information that was slowly but surely gathered, the first English edition was created which was published in 1996 under auspices of the ESH, the predecessor of the current WFHSS. In 2004 the second updated edition was published. During the past years I had the opportunity to present courses on sterile supplies in many countries, especially in Africa. It is a great experience to see the enthusiasm of all those people who want to make a difference in their own field. The book has been a tool to provide the basic information. With this 3rd edition I hope this contribution to improve sterile supply can continue.

Sterilization is a field where many exiting sciences and technologies meet: from microbiology, medicine, to mechanical and electrical engineering. A profession where life and death meet each other; in which life at micro-level is massively offered in order to protect ours. Through this sterilization almost gets a philosophical/ethical character.

This book wants to be an introduction for all those that get in touch with this fascinating field, which offers an essential contribution to the safe treatment of the many patients, who thus put their lives into our hands.

|

Jan Huijs, HEART Consultancy, Renkum, The Netherlands, April 2010 |

St. Mary’s Children and Community Hospital Umuowa upgrades its Sterile supply

St Mary’s Hospital Umuowa upgrades its Sterile supply

In December 2013 the St. Mary’s Children and Community Hospital opened its doors. At the time the CSSD was equipped with an advanced autoclave for the sterilization department: A Matachana LR80-1. At the time it was installed it was anticipated that the machine was not suitable for its setting. Soon indeed it broke down and since 2014 the hospital had to rely on a pressure/cooker type autoclave. A new more basic autoclave was procured and materials for the repair of the Matachana autoclave were ordered and received early in 2015. In October 2015 the Dutch consultant Jan Huijs and his Nigerian colleague James Orsugh could come for a 3 week visit to install the new autoclave, repair the Matachana autoclave, offer advice and perform training for staff. The new autoclave could be installed in the CSSD. In collaboration with the technical team the autoclave was connected to the electricity supply, water supply and drain. Test running resulted in optimizing the pack size for the process. The Matachana autoclave had been worked on by other technicians, however could not be repaired. Wiring was loosened and changed; water level sensors of the steam generator interchanged. The vacuum pump was considered the major problem. During the visit the problems were analysed; the vacuum pump exchanged and issues related to the wiring resolved. Test running could be done again. However the machine allowed only a single reliable cycle at the beginning of the day when the water is still cold. A cycle per day would however remain sufficient production per day. The manufacturer is being contacted on this issue. The small pressure cooker that was in a very poor state: a plastic tube used to close a the connection of a broken down valve was about to burst; the pressure gauge was not working; the electrical connection is extremely poor and dangerous and the trivet for keeping the tray above the heating element was causing corrosion and rust sediments on the chamber, tray and instruments. The autoclave received a full overhaul with new trivet, pressure gauge and adequate closing of the hole of the missing valve. An adequate sterilization cycle has was established. Storage time of goods sterilize in the pressure cooker has been too long resulting in serious growth of fungi in sterile packs. The storage time for these packs was reduced to a maximum of 2 days. Cleaning of instruments revealed short comings: corrosion and serious residues on instruments ready for use were observed. Cleaning practice was improved and new brushes were issued. Packaging of sterile packs caused the need of complicated handling for opening them; thus leading to increase chances of recontamination. Adequate packaging methods were trained on, enabling aseptic opening of the packs. In order to improve the quality and procedures in sterile supply a 5 day training was organized. It included a theoretical part during with principles of infection control were explained. Followed by the basics on physics required to understand the operation of the steam sterilizers. The construction and operation of the sterilizers were explained and followed by hands on practicals on their operation in the sterilization department. The training started with an pre test and was followed by a post test thus enabling evaluation of the performance of the students. The score increased an average of 20%, a considerable improvement. All participants that attended the full training received a certificate of attendance. With and enthusiastic song and lots of happiness outside at the entrance of the hospital the training was closed. The training revealed a desperate need on improving knowledge on basic issues such as quantities and units, principles of physics and calculations! Within the medical field such basic knowledge is crucial and it is strongly recommend to organize more training in order to improve these skills. During the last days still several workshops were held on cleaning packaging and a training session on the Matachana autoclave. In order to improve infection prevention in the OR building a red line was marked in the lobby thus separating the dirty area and clean area of the building. Beyond the red line a strict clothing protocol will be in place. With all lessons learnt, the new equipment and procedures the hospital made another quantum leap in its mission in improving patient care. It was great to be involved in this effort!

Renkum, The Netherlands, 31-12-2015. Jan Huijs

Aftermath of the Ebola Crisis: Liberia Hospitals improving their sterile supply

2014-12-01: JF Kennedy Medical Centre, Monrovia, Liberia: The Maternity Hospital, supported through the Japanese Government

The year 2014, Liberia, West Africa. The country is confronted with the most deadly disease in recent history: Ebola. Public life including the health system have come to a standstill. At the time the German Red Cross assists the national John F Kennedy Medical Centre in Monrovia with the establishment of a triage unit, where all incoming patients are tested on signs of Ebola. The representing officer of the Red Cross is invited to visit the neighboring Japanese-Liberian Friendship Maternity Hospital, attached the Medical Center. The Maternity Hospital has been established in 1983 with the support of the Japanese International Cooperation Agency JICA.